Oloa

Tungsten Solid Carbide Rods

Carbide Rods Faʻamatalaga

Tungsten carbide rods o loʻo faʻaaogaina lautele mo le fatuina o mea faʻapipiʻi malosi, e pei o mill pito, vili, reamers, milling cutters, stamping, ma fuaina meafaigaluega i alamanuia eseese. Kedel Tool gaosia pito i luga ma tumau lelei carbide rods i togi eseese e aofia ai K20F, K25F, ma isi. O loʻo maua se filifiliga faʻapitoa faʻapitoa o tungsten carbide rods i itu eseese, ma matou te ofoina atu foi auaunaga faʻapitoa e tusa ai ma ou manaʻoga. I le avea ai o se tagata gaosi ISO, e faʻaaoga e Kedeltool mea e sili ona lelei e faʻamautinoa ai le lelei ma le faʻatinoga o a tatou carbide rods. Fa'atasi ai ma su'esu'ega lelei, e mafai ona matou fa'amautinoa le lelei o le tulaga i totonu o vaega ta'itasi.

Kedel Carbide Rod Ituaiga

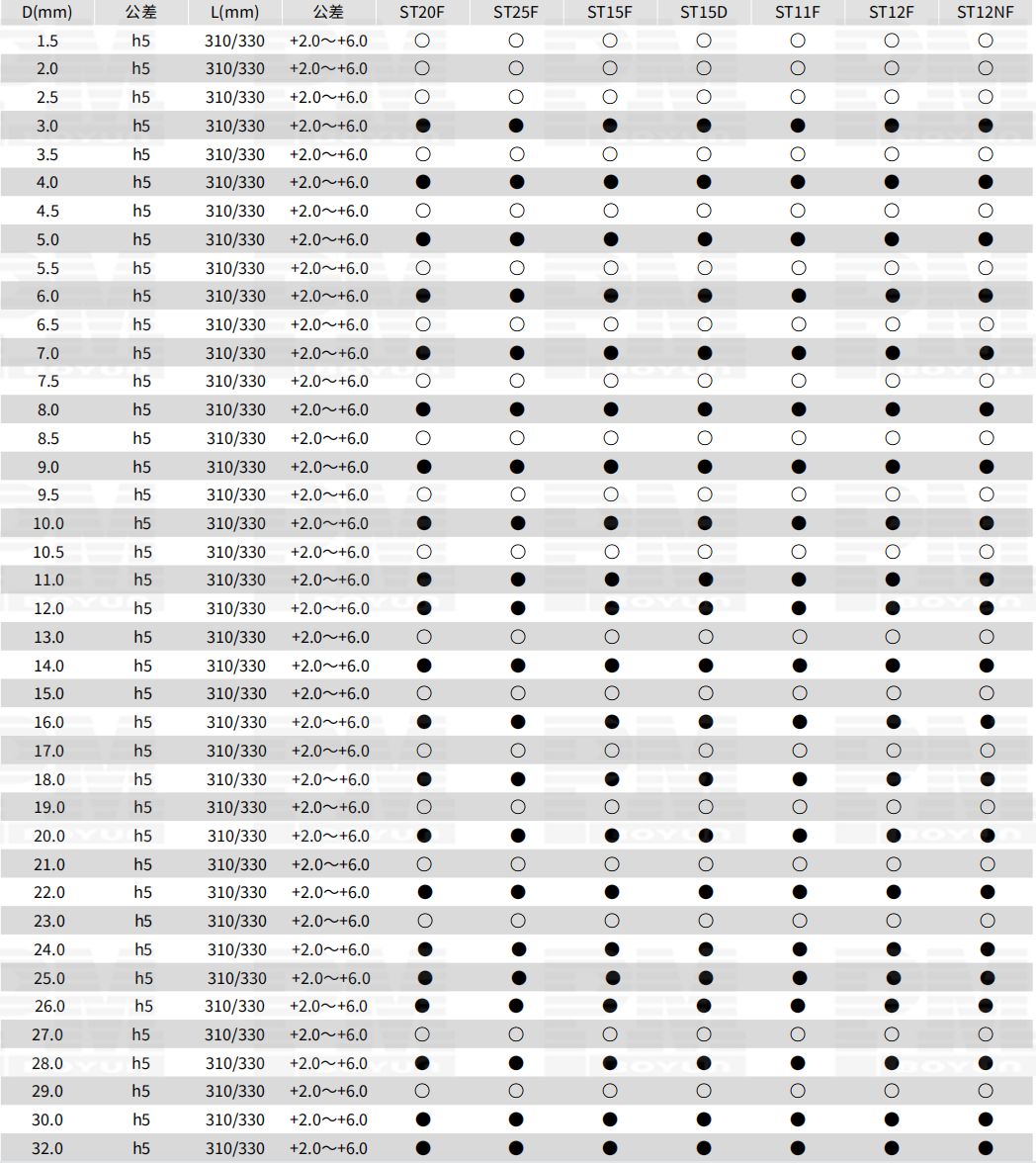

1. Malolo Puipuiga Rods i Metrics

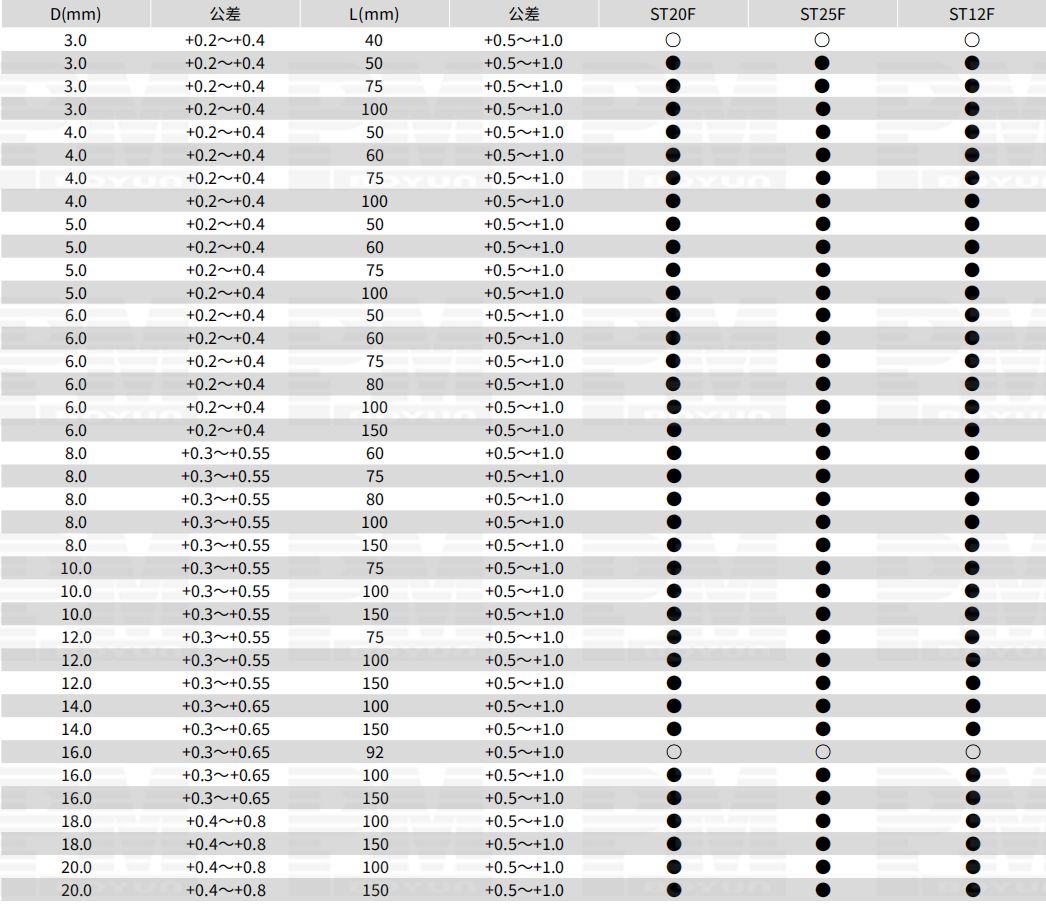

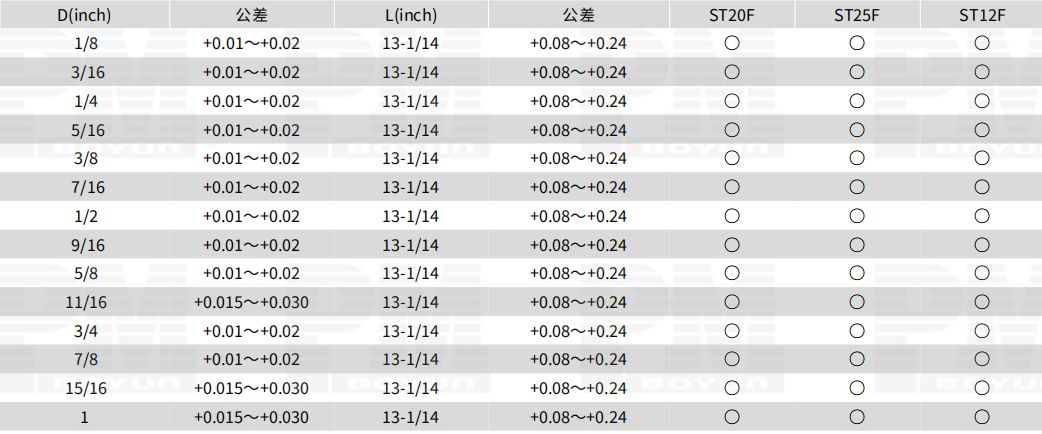

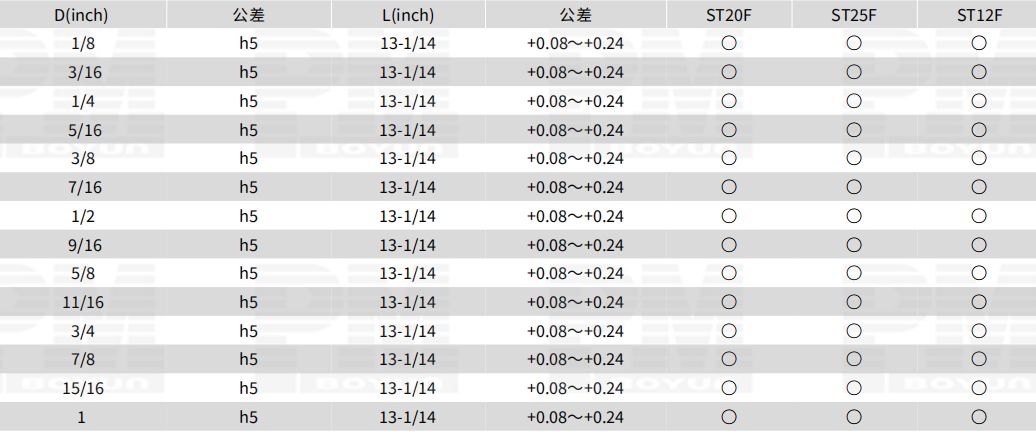

2. O U'amea Mausali i Inisi

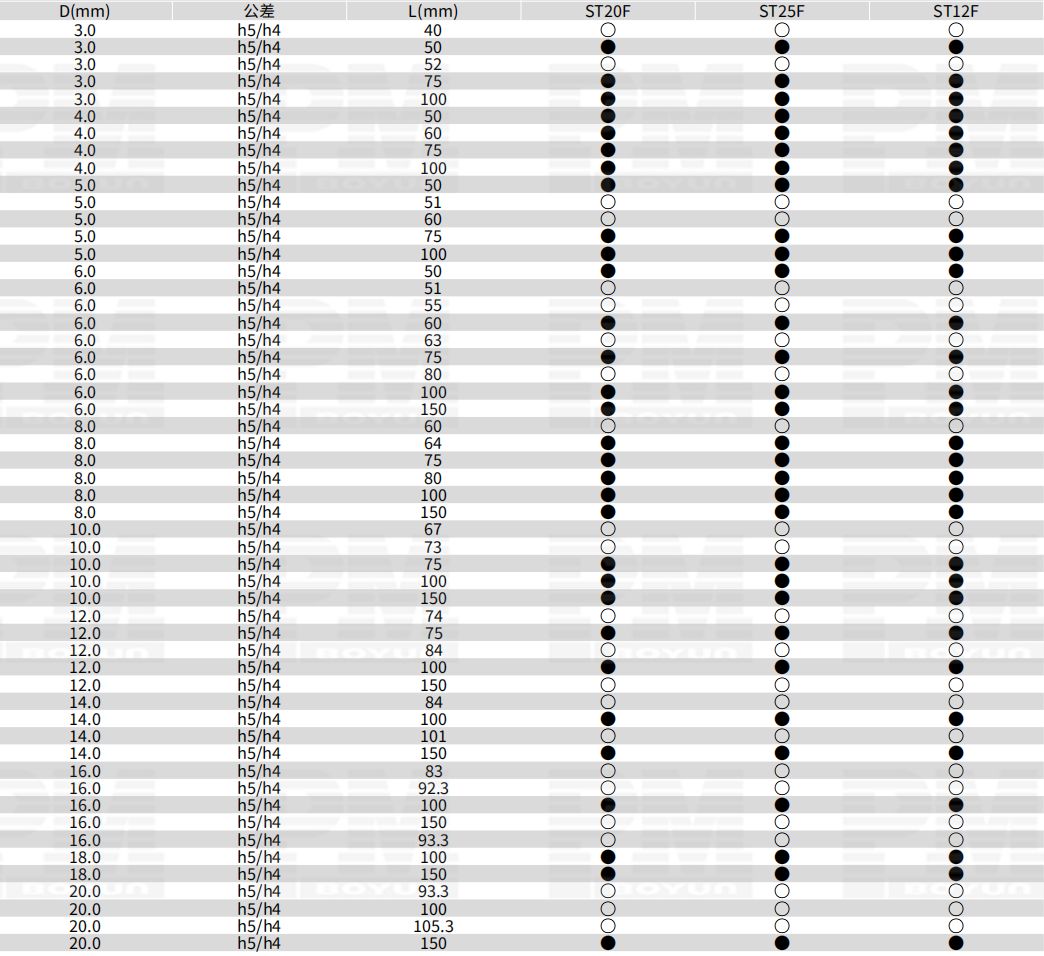

3. Tu'u Avanoa (Chamfered)

4. Avanoa Fa'ai'u (Chamfered)

5. U'a Carbide ma se Pu sa'o Central Coolant

6. U'a Carbide ma Pu Sa'o Fa'amalie Lua

Uiga Carbide Rod

1. Faia i le tulaga maualuga tungsten carbide superfine pauta

2. Mea faigaluega sa'o ma le ogaumu 10MPa HIP-Sinter fa'ata'atia le gaosiga.

3. Malosi maualuga ma le malosi maualuga

4. Fa'apitoa fa'apitoa: Ma'a'a mumu, fa'aofuofu fa'asao, maualuga elasticity modulus, TRS, mautu kemisi, a'afiaga fa'aletonu, fa'aitiitia le fa'alauteleina o le fa'aogaina, fa'avevela vevela ma fa'aulu eletise tutusa ma le u'amea.

5. Fa'atekonolosi fa'apitoa: sintering maualuga maualuga o le vevela vevela maualuga. Faʻaitiitia le porosity, faʻaititia le compactness ma mea faʻainisinia. Vasega eseese, ituaiga ma lapopoa.

6. Fa'ailoga eseese mo lau fa'amatalaga.

Laisene masani

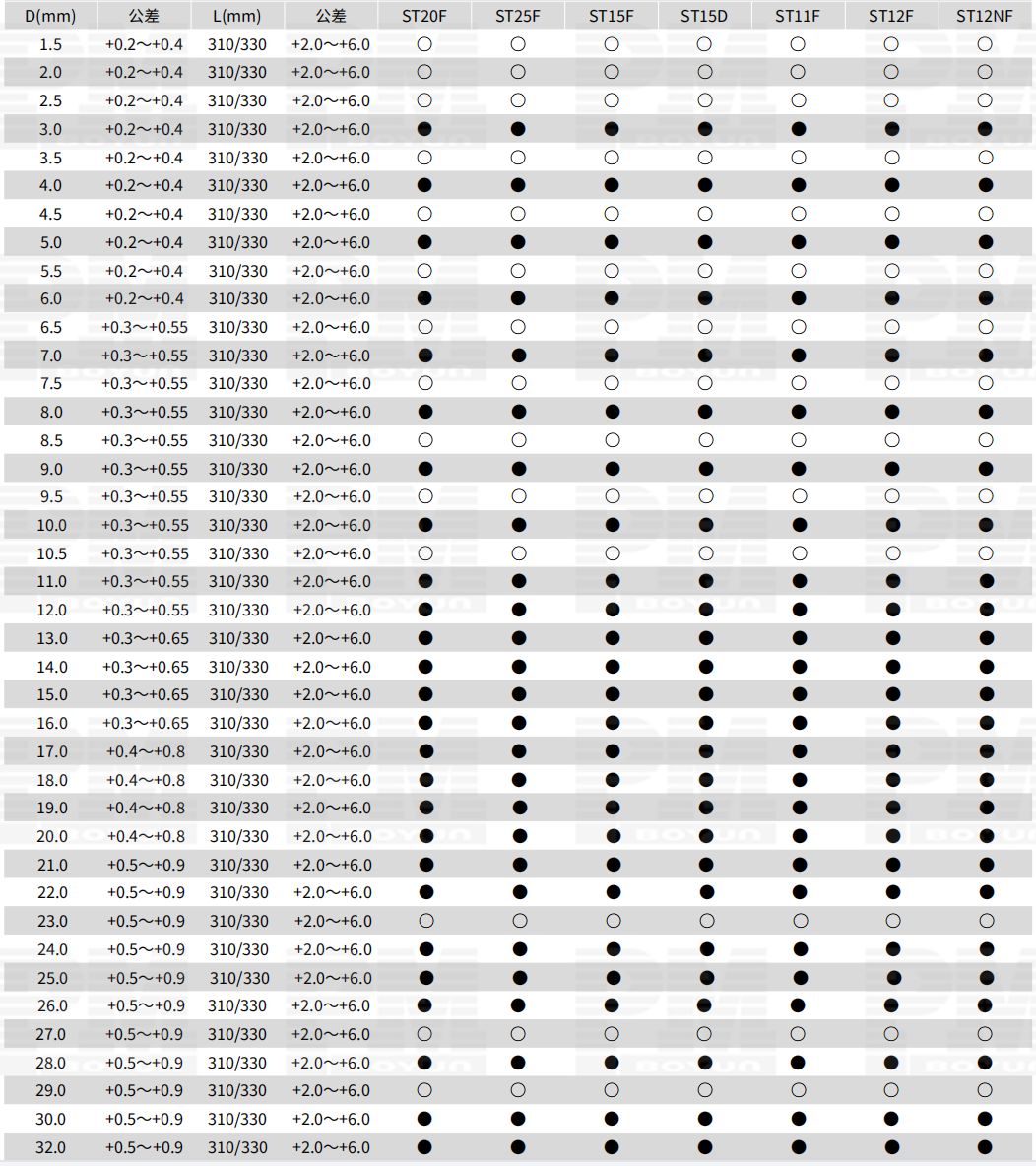

Lisi Vasega

| Vasega Folasaga ile Carbide Rods | |||||||

| Vasega | Co % | WC le tele o saito | HRA | HV | Malosi (g/cm³) | Malosi o le punou (MPa) | Malosi gau(MNm-3/2) |

| KT10F | 6 | Submicron | 92.9 | 1840 | 14.8 | 3800 | 10 |

| KT10UF | 6 | fa'alelei | 93.8 | 2040 | 14.7 | 3200 | 9 |

| KT10NF | 6 | nanometer | 94.5 | 2180 | 14.6 | 4000 | 9 |

| KT10C | 7 | Lelei | 90.7 | 1480 | 14.7 | 3800 | 12 |

| KT11F | 8 | Submicron | 92.3 | 1720 | 14.6 | 4100 | 10 |

| KT11UF | 8 | fa'alelei | 93.5 | 1960 | 14.5 | 3000 | 9 |

| KT12F | 9 | fa'alelei | 93.5 | 1960 | 14.4 | 4500 | 10 |

| KT12NF | 9 | nanometer | 94.2 | 2100 | 14.3 | 4800 | 9 |

| KT15D | 9 | Submicron | 91.2 | 1520 | 14.4 | 4000 | 13 |

| KT15F | 10 | Submicron | 92.0 | 1670 | 14.3 | 4000 | 11 |

| KT20F | 10 | Submicron | 91.7 | 1620 | 14.4 | 4300 | 11 |

| KT20D | 10 | Submicron | 92.0 | 1670 | 14.3 | 4500 | 11 |

| KT25F | 12 | fa'alelei | 92.4 | 1740 | 14.1 | 5100 | 10 |

| KT25EF | 12 | fa'alelei | 92.2 | 1700 | 14.1 | 4800 | 10 |

| KT25D | 12 | fa'alelei | 91.5 | 1570 | 14.2 | 4200 | 13 |

| KT37NF | 15 | nanometer | 92.0 | 1670 | 13.8 | 4800 | 10 |

Mo nisi faʻamatalaga (MOQ, tau, tuʻuina atu) pe afai e te manaʻomia ni auʻaunaga faʻapitoa, faʻamolemole talosagaina se upusii.