Oloa

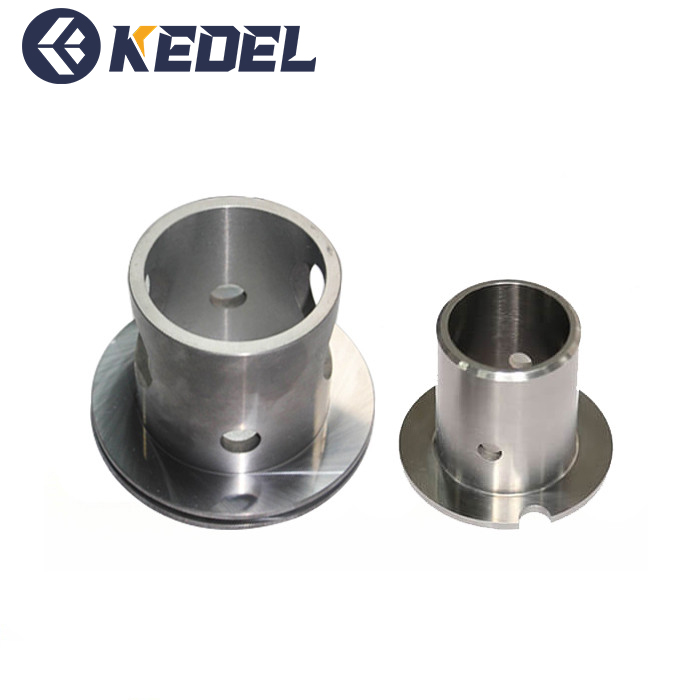

Fa'apitoa Tungsten carbide Bushing Shaft Sleeve

Folasaga o oloa

Tungsten carbide bush talosaga e lautele, o se masini e puipuia ai se vasega o vaega. O loʻo i totonu o le galuega moni ma o le matafaioi ma le faʻamoemoe o lona siosiomaga faʻaoga e iai se mafutaga sili. Valve talosaga, bushings faʻapipiʻi i totonu o le valve stem cap mailei, ina ia faʻaitiitia ai le alavai leakage, e faʻamaufaʻailogaina; faʻaogaina talosaga, le faʻaogaina o le vao e faʻaitiitia ai le ofuina i le va o le faʻamau ma le nofoa nofoa, aloese mai le va i le va o le pu ma le faʻateleina o le pu ma isi. Tungsten carbide togavao gaosiga ma le faagasologa o le malosi-maualuga, e mafai ona tatalia uta faaumiumi, ma le mautu kemisi maualuga, alkali, ava malosi, eter, hydrocarbons, acid, suauu, detergent, vai (vai vai), ma e leai se manogi , e le oona, tasteless, non-ele uiga, lona faaaogaina lautele i le alamanuia petrochemical mo Submerged Suauu pamu, pamu vai, pamu slurry.

Oloa Fa'ailoga

1. Tungsten Carbide Bearing Bushings o loʻo i ai uiga o le maualuga o le ofuina o le ofuina, maualuga le faʻafefeteina ma mea lelei compressive.

2. O lo'o fa'aaogaina lautele i pisinisi petrochemical ma isi alamanuia e mana'omia ai meatotino maualuluga o le fa'alava fa'amau po'o lima lima.

3. Tungsten carbide BEARING o le mea faavae i totonu o mea frictional. Latou te faʻaaogaina lautele e avea ma vaega autu mo faʻamaufaʻailoga. Ma o laʻau e faʻaaogaina lautele i le gaosiga o le petrochemical ona o ana faʻatinoga sili ona lelei e pei o le ofuina o le gafatia, anti corrosion ma isi.

Gaosiga Fa'agasologa

Milina - Fa'avasegaina pe'ā mana'omia - Su'e Susū - Fa'amago - Fa'a'oloa - Lomiga--Sinter--Su'esu'ega--Afike.

oloa fa'atatau

Tungsten Carbide Bushings

Lima Carbide mo pamu centrifugal

Tungsten Drill Guide

Lima Manu'a Tu'i Carbide

Poloka Carbide

Polo Valve Carbide.

Tungsten Carbide Valve Nofo ma Po'a

Tungsten Carbide Suau'u ma Kasa Faanatura La'ei Vaega ma Vaega

Tungsten Carbide Nozzles

Tungsten Carbide High Pressure Pump Vaega

Tungsten Carbide mo -Tafe Tafe

Vaega Pumu Centrifugal

Centrifugal Carbide La'ei Tile

Ata lapopoa o oloa

laulau meafaitino

| Vasega | ISO | Fa'amatalaga | Faʻaaogaina o le tungsten carbide | ||

| Malosi | TRS | Malosi | |||

| G/Cm3 | N/mm2 | HRA | |||

| YG06X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | Agava'a mo le fa'aogaina o u'amea fa'a'a'alili, u'amea u'amea, u'amea fa'ato'a ma u'amea. Agava'a fo'i mo le fa'aogaina o u'amea masani. |

| YG06 | K20 | 14.7-15. 1 | ≥1670 | ≥89.5 | Agava'a mo le fa'auma ma le fa'auma fa'auma mo le u'amea lafo, u'amea e le fa'a'u'u, u'amea ma mea e le fa'afefeteina. E agavaa foi mo le tusi uaea mo le uamea ma le u'amea e le o le u'amea, vili eletise mo le fa'aogaina o le geology ma le vili uamea ma isi. |

| YG08 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | Agavaʻa mo le faʻaogaina o le uʻamea uʻamea, uʻamea e le o le uʻamea, mea e le uʻamea, ata o uʻamea, uʻamea e le faʻafefe ma paipa, faʻataʻitaʻiga eseese mo le faʻaogaina o le geology, meafaigaluega mo le gaosiga o masini ma le ofuina o vaega. |

| YG09 | K30-M30 | 14.5-14.8 | ≥2300 | ≥91.5 | Agavaa mo le maualalo o le saoasaoa machining talatala, vili titanium alloy ma refractory u'amea, aemaise mo meafaigaluega tipi ma tui silika. |

| YG11C | K40 | 14-.3-14.6 | ≥2100 | ≥86.5 | Agava'a mo le fa'aliliina o fa'ata'ita'iga mo vili ma'a mamafa: vili e mafai ona fa'aaogaina mo le viliina o pu loloto, ta'avale vili ma'a ma isi. |

| YG15 | K40 | 13.9-14.1 | ≥2020 | ≥86.5 | Agavaa mo le viliina maa malo, pa u'amea ma fua fa'amalosi maualuga, ata paipa, tu'i meafaigaluega, kapoti autu o pauta metallurgy molders otometi ma isi. |

| YG20 | 13.4-14.8 | ≥2480 | ≥83.5 | Agava'a mo le faia o mate e maualalo le a'afiaga e pei o le tu'iina o vaega o le uati, atigi maa, tama'i pulou sikulima ma isi. | |

| YG25 | 13.4-14.8 | ≥2480 | ≥82.5 | Agavaʻa mo le faia o le faʻailoga o le ulutala malulu, faʻamaufaʻailoga malulu ma le oomi malulu faʻaaogaina mo le gaosiga o vaega masani, bearings ma isi. | |